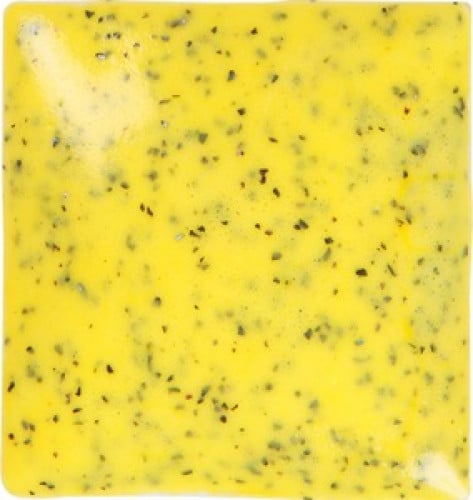

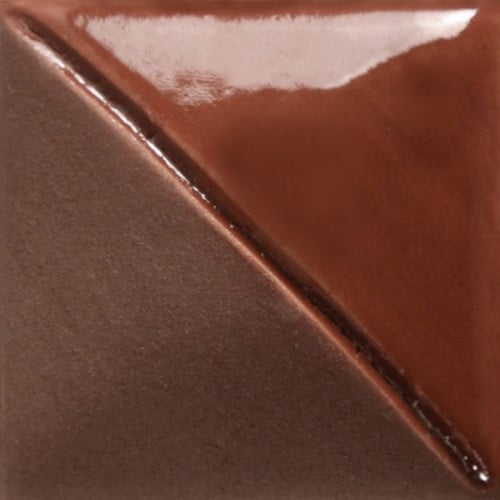

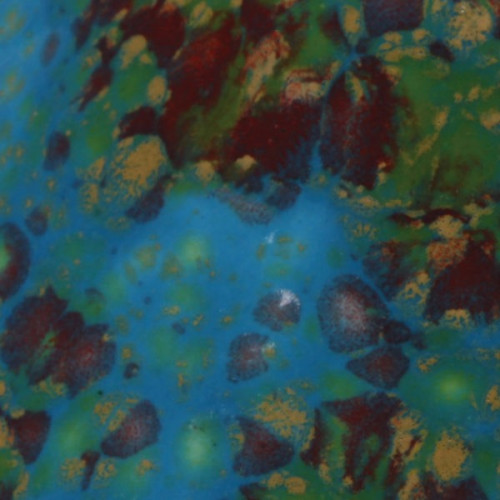

Fe2O3. Iron oxide red is the most common colorant in ceramics and contains the highest amount of iron. It is commercially available as a very fine, fine powder made by grinding raw materials or heat treatment of iron/ferric sulfate or ferric hydroxide. During firing, all irons typically degrade and produce similar colors in glazes and clay bodies (although they contain different amounts of iron metal per gram of powder). In the oxidation process, iron is an important source of brown, red and brown colors in glazes and bodies. Iron red colors, for example, depend on the crystallization of iron in a liquid glass matrix and require the presence of large amounts of iron (eg 25%). The red color of terracotta bodies comes from iron, usually around 5% or more, and depends on whether the body is porous. When these bodies are fired to higher temperatures, the color turns dark red and finally brown. The story is similar to Medium Fire Corpses. In the reduction of shooting changes his character to an incredible extent, it changes into a flow, a very energetic flow. The glass transition of stable iron at cone 6-10 in oxidation will run out in reduction. The iron in reductive glazes is known for producing very attractive earthy brown tones. Greens, grays, and reds can also be obtained depending on the chemistry of the glaze and the amount of iron. Ancient Chinese celadons, for example, contain about 2-3% iron. Particulate iron inclusions "blossom" the reduced clay bodies during firing, creating large specks that bleed through the glass. Source: Digital Fire.